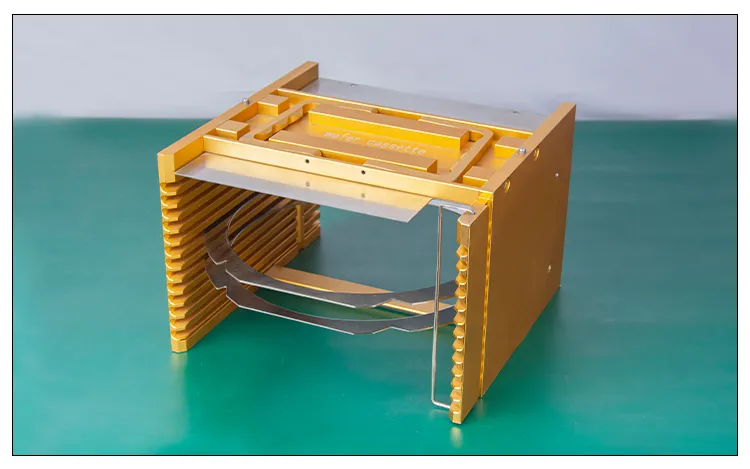

Wafer Shipping Box

Weeprofab supplies an extensive range of silicone sheets. This material is widely used for several applications due to its easy-to-manufacture and shaping process. It can be custom cut according to your needs to suit your requirements.

- 600° F / 315° C temperature rating

- Highly durable and long-lasting

- Great sealing capabilities

- Custom sizes available

Uncompromised Protection for Wafer Transport

Shield wafers from ESD, vibration & contamination. Anti – static, cushioned design for labs & institutes—global shipping ready.

Introduction to Wafer Shipping Box

A Wafer Shipping Box is a high-precision protective container designed for semiconductor wafers during storage, transportation, and production logistics, ensuring wafer integrity and cleanliness in complex environments.

Its core structure uses special anti-static and impact-resistant materials (such as polycarbonate, aluminum alloy, or modified POM), combined with sealed designs and cushioning systems to effectively withstand vibrations, temperature/humidity fluctuations, and electrostatic interference.

With mechanical interfaces and dimensions compliant with SEMI international standards, wafer shipping boxes seamlessly integrate with automated semiconductor production line equipment (e.g., robotic arms, FOUP transfer systems) for efficient and safe material handling.

Some advanced models incorporate functions like temperature/humidity monitoring, vacuum sealing, or RFID tracing to meet the rigorous environmental control and data management requirements of advanced manufacturing processes.

Faqs:

1. What materials are your Wafer Shipping Boxes made of?

Our Wafer Shipping Boxes are crafted from high – purity polypropylene (PP) or polystyrene (PS). These materials are chosen for their excellent chemical resistance, low outgassing properties, and ability to minimize particle generation, ensuring a clean and safe environment for your wafers during transit.

2. What is the maximum number of wafers each box can hold?

The capacity varies by box size. Our standard boxes can hold anywhere from 1 to 25 wafers. For example, our smaller – sized boxes, suitable for 2 – inch wafers, typically hold 1 – 5 wafers, while the larger 8 – inch wafer boxes can securely accommodate up to 25 wafers.

3. Are your shipping boxes suitable for long - distance international shipping?

Absolutely. Our Wafer Shipping Boxes are engineered to withstand the rigors of long – distance transportation, including international shipping via air or sea. They are designed with robust construction, secure closures, and appropriate cushioning to protect wafers during extended journeys and multiple handling procedures.

4. Do you offer boxes in different sizes to fit various wafer diameters?

We offer a comprehensive range of box sizes to fit wafers with diameters from 50 mm (2 – inch) up to 300 mm (12 – inch). Whether you need to ship small – sized wafers for micro – scale research or large – diameter wafers for advanced semiconductor manufacturing, we have the right box for you.

5. Can I customize the interior of the Wafer Shipping Box to better secure my wafers?

Yes, customization options for the interior are available. We can provide custom – designed inserts, dividers, or holders to ensure a snug fit for your specific wafer sizes and types. This helps to minimize movement and potential damage during shipping.

6. How do your boxes prevent vibration - related damage to wafers?

Our boxes are designed with internal structures and cushioning materials that absorb and dampen vibrations. Additionally, the tight – fitting lids and secure closures prevent the wafers from shifting inside the box, reducing the risk of damage caused by vibrations during transportation.

7. Are the boxes cleanroom - compatible if I need to use them in a cleanroom environment before shipping?

Yes, our Wafer Shipping Boxes are cleanroom – compatible. They are manufactured in cleanroom – like conditions and are made from materials that do not shed particles or outgas. This makes them suitable for use in cleanroom environments where wafers are prepared for shipping.

8. What is the lead time for ordering Wafer Shipping Boxes, especially for customized orders?

For standard stock items, the lead time is typically 3 – 5 business days for processing and shipping. For customized orders, depending on the complexity of the customization, the lead time can range from 2 – 4 weeks.

9. Do you provide any testing or certification for the protection capabilities of your boxes?

Yes, all our Wafer Shipping Boxes undergo rigorous in – house testing for ESD protection, vibration resistance, and particle – free performance. Additionally, we can provide certifications upon request, such as ISO – compliant quality certifications, to ensure you have confidence in the protection our boxes offer.

10. Do you offer any warranties or guarantees on your Wafer Shipping Boxes?

We offer a 1 – year warranty on all our Wafer Shipping Boxes. If there are any manufacturing defects or issues with the box’s performance within this period, we will replace the box free of charge. Additionally, we stand by the quality of our products and are committed to ensuring your satisfaction.

11. Can I order samples of the Wafer Shipping Boxes before placing a bulk order?

Yes, we provide sample services. You can request samples of our standard box sizes. Please note that there may be a nominal fee for the samples, and you will be responsible for the shipping costs. However, the sample fee can be waived or credited towards your bulk order.

12. How are the Wafer Shipping Boxes packaged for delivery to ensure their safety during transit?

Each Wafer Shipping Box is individually wrapped in protective materials, such as bubble wrap or foam sheets, to prevent scratches and damage during transit. Multiple boxes are then packed together in a sturdy outer carton with additional cushioning materials to ensure they arrive at your location in perfect condition.

13. Can I track the shipment of my Wafer Shipping Boxes once they are dispatched?

Yes, once your order is shipped, we will provide you with a tracking number and the relevant shipping carrier’s information. You can use this tracking number to monitor the progress of your shipment online and get real – time updates on its location and estimated delivery time.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!