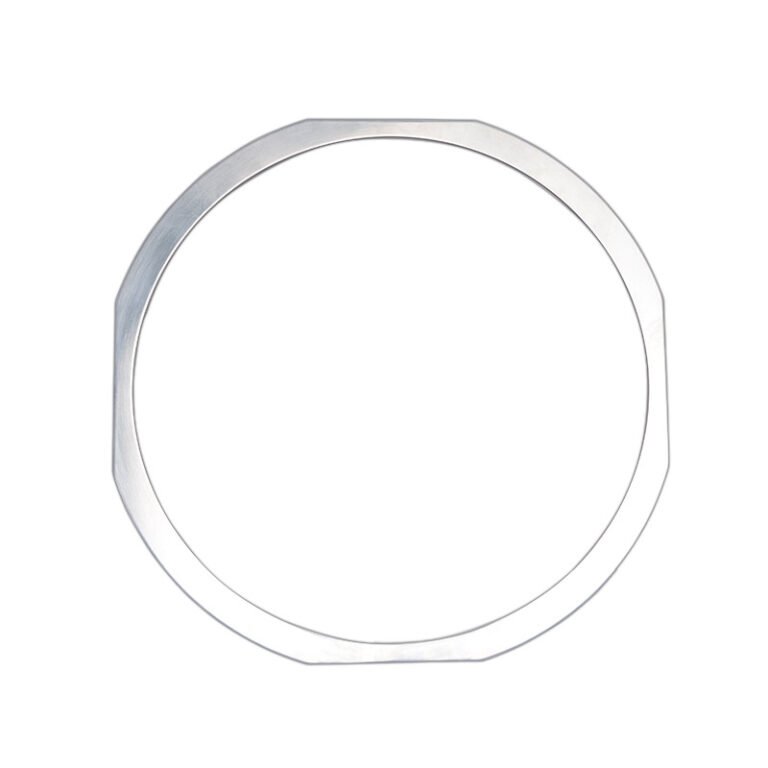

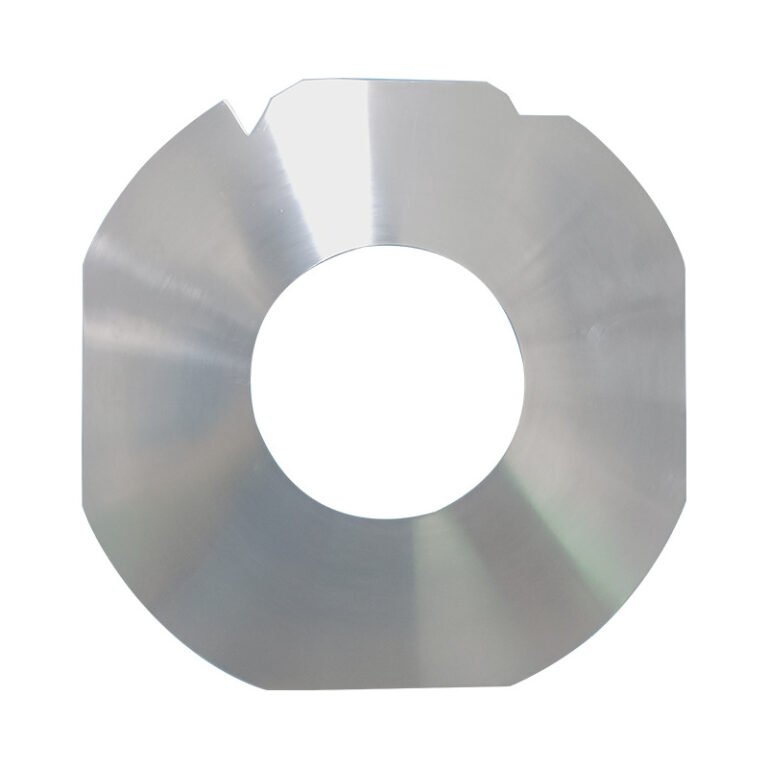

Wafer Frame Ring

Enhance your semiconductor manufacturing efficiency with our Wafer Frame Ring! Specifically designed to support and secure wafers, this high-quality ring fixture ensures your wafers remain stable and secure during processing and transportation. Made from materials that are resistant to high temperatures and corrosion, it guarantees outstanding durability and reliability.

- The ring-shaped design evenly distributes pressure, reducing the risk of wafer deformation.

- Typically made from high-strength materials to ensure durability in high-temperature and high-pressure environments.

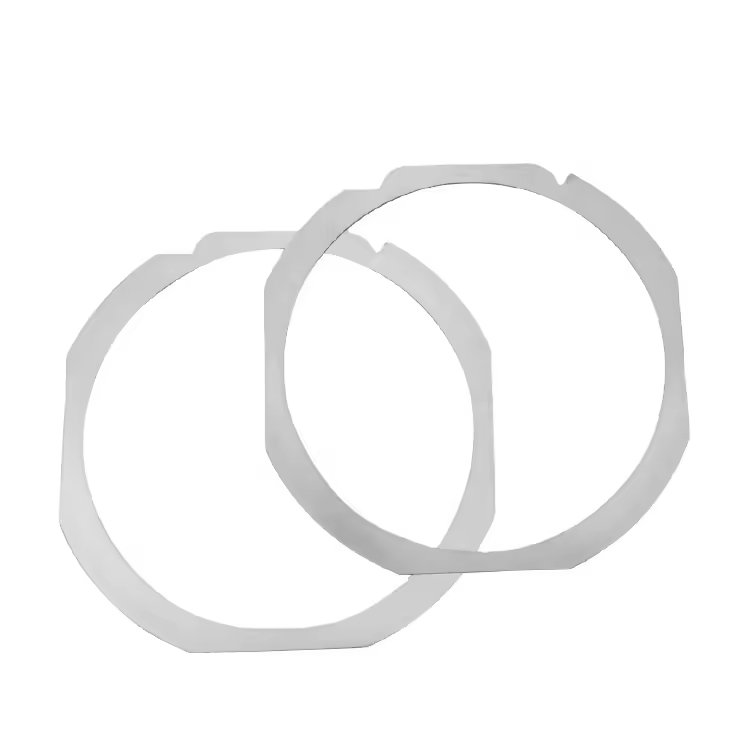

- Compatible with various wafer sizes, suitable for different specifications such as 4-inch, 6-inch, 8-inch, and 12-inch

What is Wafer Frame?

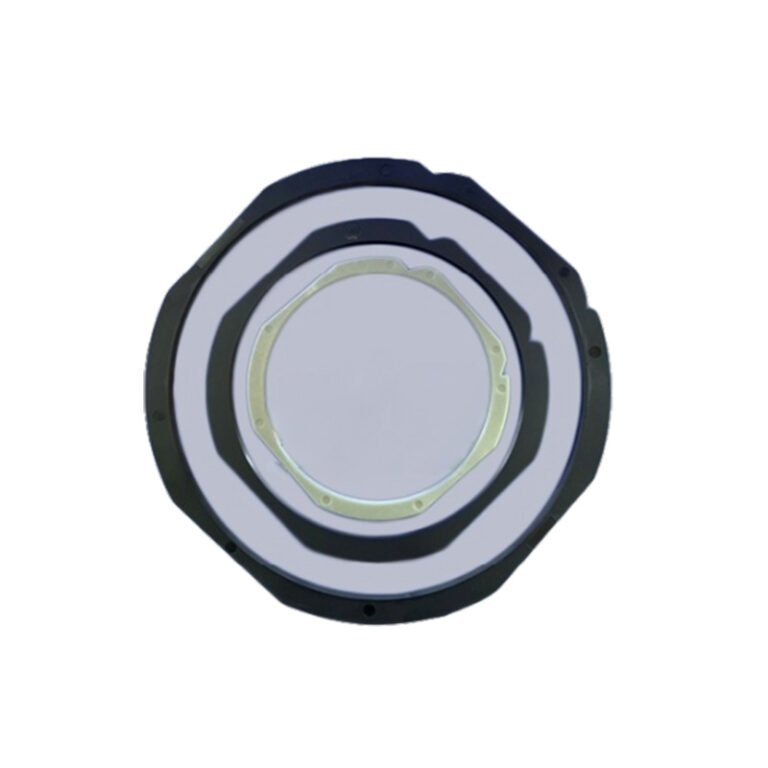

A wafer frame is a critical component in semiconductor manufacturing, primarily serving to support and protect wafers during various processes. It provides a stable platform that prevents warping and deformation while shielding wafers from physical damage and contamination during handling and transport. Typically made from high-strength materials, wafer frames are designed to withstand high temperatures and harsh chemical environments, while being lightweight for easy handling. They often feature a modular design that can be customized for specific wafer sizes, accommodating different diameters such as 4-inch, 6-inch, 8-inch, and 12-inch.

Wafer frames are used in various stages of semiconductor fabrication, including etching, deposition, and testing, enhancing workflow by allowing for easy loading and unloading in automated systems. In addition to their use in the semiconductor industry, they are also essential in the production of optical devices and micro-electromechanical systems (MEMS), highlighting their versatility. Continuous advancements in materials and design improve their performance and adaptability to new technologies, making high-quality wafer frames a worthwhile investment for reducing defects and improving overall production efficiency.

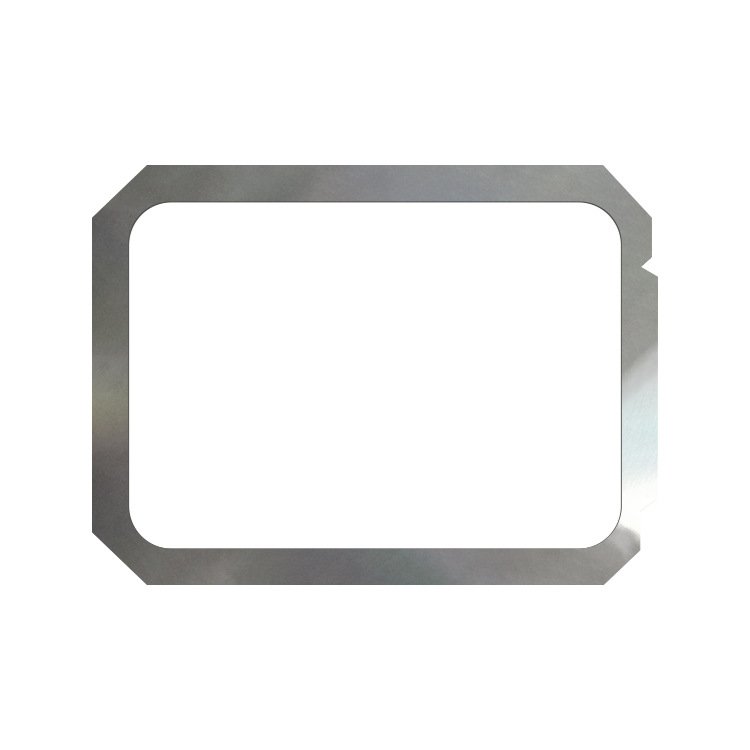

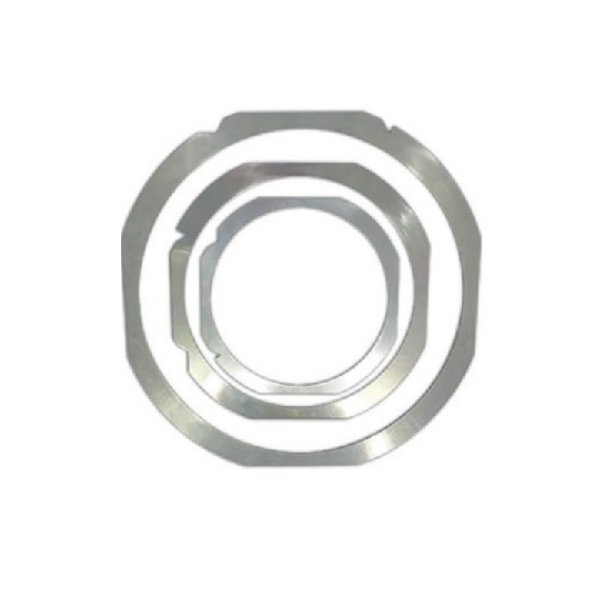

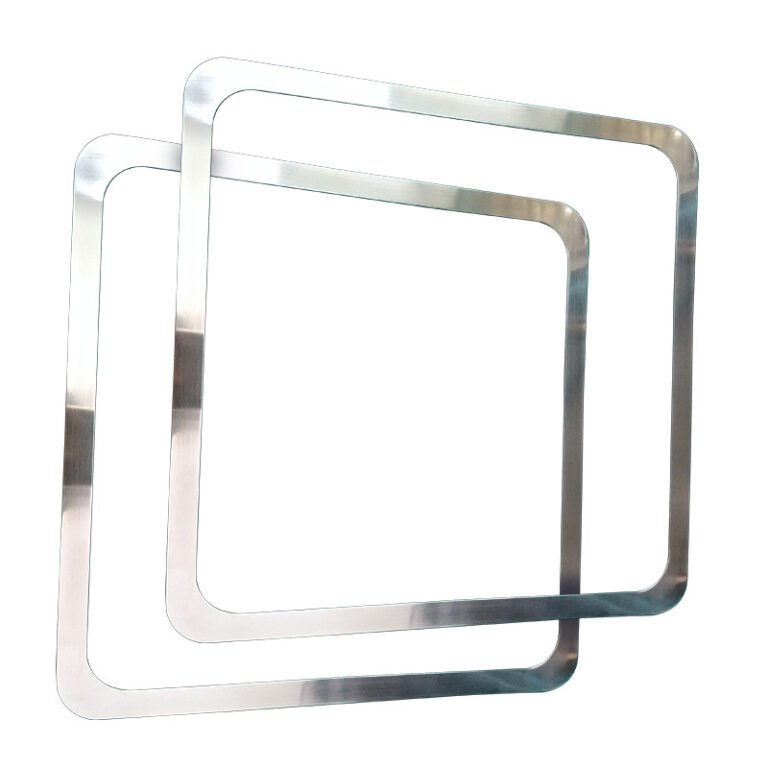

By Wafer Frame Demensions

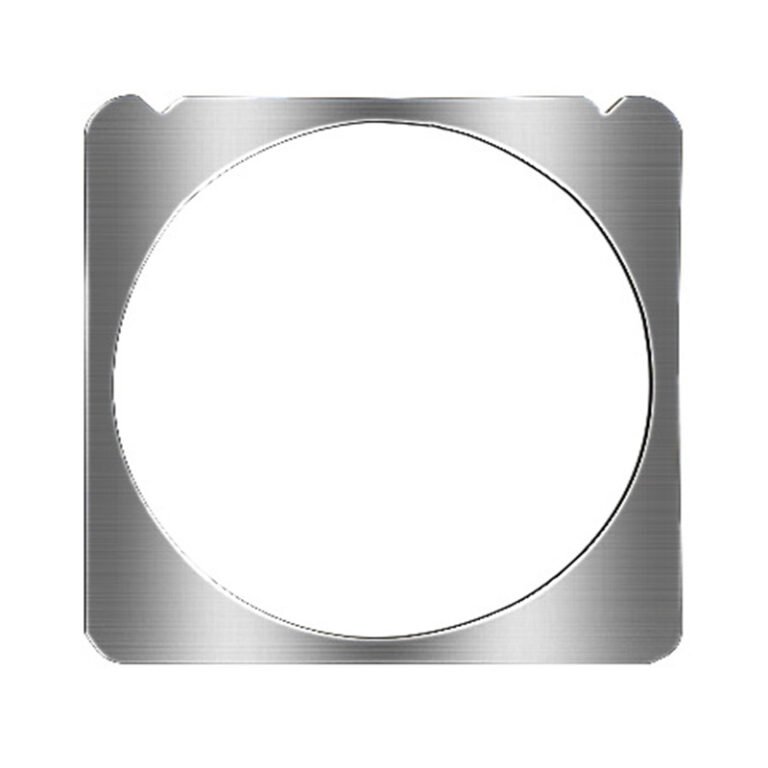

By Wafer Frame Shape

Relative Products

FAQs of Wafer Frame:

1. What special operating specifications should be followed when using wafer frames in a laboratory cleanroom environment?

When using wafer frames in a laboratory cleanroom environment, they should be double – cleaned before entering the cleanroom. Wipe the surface with cleanroom wipes and special cleaning agents. During operation, it is necessary to wear protective equipment such as cleanroom suits, masks, and gloves to avoid contamination. Opening and closing the wafer frame should be carried out inside a laminar flow hood to prevent external particles from entering.

2. What impact does the temperature and humidity environment of the laboratory have on wafer frames? How should we respond?

Excessive humidity may cause rust on the metal components of wafer frames and aging of plastic components, while too low humidity is likely to generate static electricity. The laboratory should strictly control the temperature and humidity within an appropriate range (e.g., 20 – 25°C for temperature and 40% – 60% for humidity). At the same time, temperature and humidity sensors can be placed in the storage area of wafer frames for real – time monitoring, and humidifiers and dehumidifiers can be equipped to adjust the environment.

3. How to ensure the precise positioning of wafer frames on small laboratory testing equipment?

Before use, the positional accuracy of the interface between the equipment and the wafer frame needs to be calibrated. The matching degree between the card slot and the positioning points of the equipment can be detected by measuring tools. Positioning pins or grooves can be added at the bottom or sides of the wafer frame to cooperate with the corresponding structures on the equipment, ensuring that the placement position is consistent each time. Regularly check the wear of the equipment and wafer frames, and repair or replace the components that affect positioning in a timely manner.

4. How do wafer frames cooperate with probe stations during wafer testing in the laboratory?

Place the wafer frame steadily on the stage of the probe station. Through the robotic arm of the probe station or manual operation, accurately remove the wafer from the card slot of the wafer frame and place it at the testing position. After the test is completed, put the wafer back into the wafer frame in the reverse order. During the operation, ensure that the contact points between the wafer and the probe station are clean to avoid damaging the wafer and the wafer frame.

5. How often do wafer frames used in the laboratory need to be cleaned and maintained?

The frequency of cleaning and maintenance depends on the frequency of use and the cleanliness of the laboratory environment. Generally, surface cleaning should be carried out at least once a week. If used frequently or in a high – pollution – risk environment, cleaning is required after each use. Conduct a thorough cleaning every quarter, including cleaning the internal card slots, inspecting components, and lubricating operations.

6. How to safely transport wafer frames with wafers in the laboratory?

When transporting, special wafer handling tools such as vacuum pens or robotic grippers should be used to avoid direct contact with the wafer frame and wafers by hand. Keep the transportation process stable, avoiding shaking and collisions. When multiple people are transporting, the division of labor should be clear to ensure that the wafer frame remains stable during the transportation process and prevent wafers from falling or being damaged.

7. Can different types of wafer frames be used interchangeably in the laboratory?

Different types of wafer frames have differences in design and purpose. Unless their dimensions, card slot specifications, and interface standards are exactly the same, it is not recommended to use them interchangeably. Interchangeable use may lead to problems such as wafers not being firmly fixed and incompatibility with equipment, affecting the accuracy of experimental results and the safety of wafers.

8. How should wafer frames be prepared for wafer lithography experiments in the laboratory?

Before lithography experiments, wafer frames need to be thoroughly cleaned and static – eliminated to ensure that there are no particles and static electricity on the surface. Check the flatness of the wafer frame to avoid affecting the lithography accuracy due to frame deformation. Place the wafer frame at the designated position of the lithography equipment and perform position calibration to ensure the stable position of the wafer during the lithography process.

9. What are the differences in anti - static measures for wafer frames between the laboratory and the production workshop?

Laboratories are usually smaller in scale, and more flexible anti – static measures can be adopted, such as using anti – static workbenches and wearing anti – static wristbands. For the wafer frame itself, in addition to using anti – static materials or coatings, ionizers can also be placed in local areas to neutralize surrounding static electricity. Compared with the production workshop, the laboratory pays more attention to the control of anti – static protection during a single experimental process.

10. How to store wafer frames reasonably in the limited space of the laboratory?

Customized storage racks for wafer frames can be made. Design multi – layer structures according to the height and width of the laboratory space to make full use of vertical space. Store different types and specifications of wafer frames separately and make clear labels. The storage area should be kept away from heat sources, water sources, and vibration sources to ensure the safe storage of wafer frames.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!