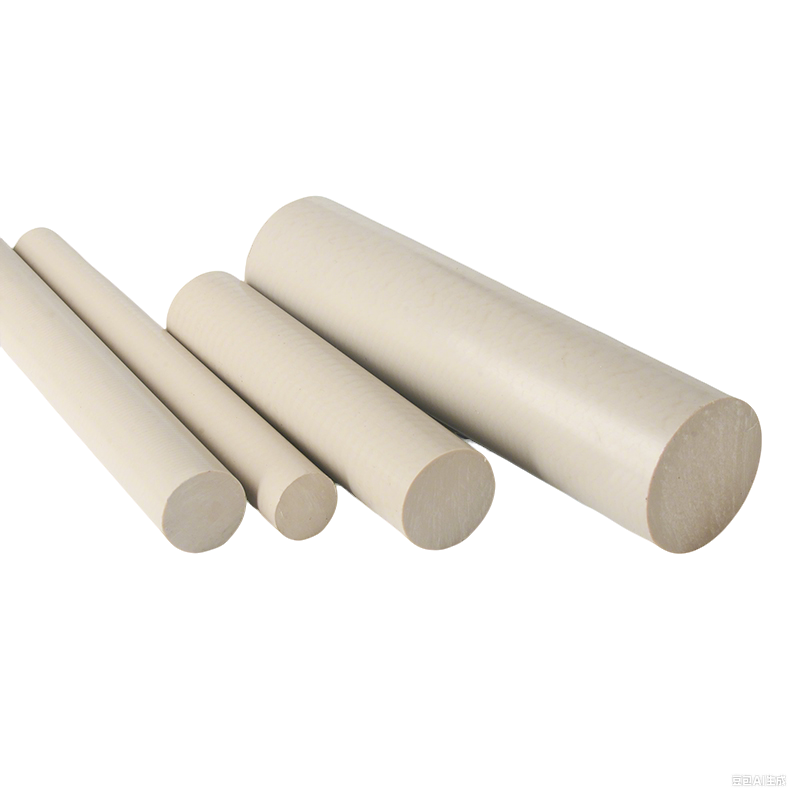

Peek Rods

- Exceptional heat resistance (up to 260°C) and chemical resilience against harsh solvents

- Superior mechanical strength for reliable performance in demanding conditions

- Custom-crafted to your specs, in any diameter or length

- Self-lubricating properties to reduce maintenance needs

Peek Rods Manufacturer & Supplier - Supwafer

When it comes to high – performance PEEK rods, Supwafer stands as an unrivaled leader in the industry. Our PEEK rods are engineered to perfection, offering a plethora of benefits that make them the top choice for a wide range of critical applications.

Exceptional Material Properties

Superior Mechanical Performance

Precision Manufacturing for Custom Solutions

We understand that every application has unique requirements. That’s why Supwafer offers a high – level of customization for our PEEK rods. Our state-of-the-art manufacturing facilities are equipped with advanced CNC machining capabilities, allowing us to produce rods in any diameter, length, or custom shape you need. Whether you require a standard – sized rod for a common application or a highly specialized, complex – shaped component for a cutting – edge research project, we have the expertise and technology to deliver.

Why Choose Supwafer?

- Quality Assurance: We adhere to strict quality control measures at every stage of production to ensure that our PEEK rods meet the highest international standards. Our products are thoroughly tested for material properties, dimensional accuracy, and performance before leaving our facility.

- Technical Expertise: Our team of experienced engineers and technicians has in – depth knowledge of PEEK materials and their applications. We can provide expert advice and technical support to help you select the right PEEK rod for your specific needs and assist with any design or engineering challenges you may face.

- Reliable Supply: With our efficient production processes and large – scale manufacturing capabilities, we can ensure a reliable and timely supply of PEEK rods, even for high – volume orders. We understand the importance of meeting your project deadlines and strive to provide seamless service.

FAQs:

1. How does PEEK’s chemical resistance hold up against common semiconductor etchants (e.g., HF, H₂SO₄) and cleansers?

PEEK exhibits exceptional resistance to most semiconductor process chemicals, including hydrofluoric acid (HF, except concentrated/boiling conditions) and sulfuric acid (H₂SO₄). Unlike metals/plastics prone to corrosion or leaching, PEEK maintains structural integrity, minimizing particle generation or chemical outgassing that could contaminate wafers or alter process chemistry.

2. Can PEEK rods introduce contaminants (particles, ions) during wafer handling?

No—PEEK is inherently low – outgassing and low – particle – shedding. Its ultra – smooth machined surfaces (achievable with precision CNC) and chemical inertness ensure it won’t release particles or ions, critical for maintaining sub – nanometer cleanliness in advanced node (≤5nm) wafer processing.

3. Does PEEK maintain dimensional stability under thermal cycling (e.g., 20°C to 300°C) in annealing/ALD processes?

Yes. PEEK’s glass transition temperature (T₀ ≈ 143°C) and continuous use temp (up to 260°C) allow stable performance in thermal cycles. Its coefficient of thermal expansion (CTE ≈ 3.5×10⁻⁵ /°C) closely matches silicon (CTE ≈ 2.6×10⁻⁶ /°C), minimizing thermal stress in wafer – contact fixtures during rapid heating/cooling.

4. How does PEEK’s strength compare to stainless steel for high - precision wafer alignment tools?

PEEK has ~80% of stainless steel’s tensile strength (90 MPa vs. 110 MPa for 304 SS) but offers superior advantages: lighter weight (density 1.3 g/cm³ vs. 7.9 g/cm³), no magnetic interference, and no metal – ion contamination. For precision alignment (e.g., sub – 10μm accuracy), PEEK’s low wear and self – lubricity reduce tool drift over time.

5. How many thermal cycles can PEEK rods withstand in R & D prototyping before failure?

PEEK retains >90% mechanical strength after 1,000+ thermal cycles (20–260°C). For R & D labs running iterative tests (e.g., 100–200 cycles per experiment), PEEK components outlast plastic alternatives (e.g., POM, PTFE) and reduce replacement frequency.

6. Is PEEK cost - effective for small - batch R & D vs. custom metal alloys?

For low – volume prototyping (<100 parts), PEEK is often cheaper. Metal alloy tooling (e.g., Invar for CTE matching) requires expensive molds, while PEEK rods are cut/machined “on – demand” with standard CNC equipment, slashing upfront costs for lab – scale projects.

7. Can PEEK rods integrate with 2D - material (e.g., graphene, MoS₂) transfer processes?

Yes—PEEK’s soft – yet – strong surface (when polished to Ra < 0.2μm) minimizes damage to fragile 2D materials during transfer. Its chemical inertness also prevents reactions with 2D material surfaces, preserving their electronic properties for device fabrication.

8. What’s the best way to clean PEEK rods after contact with aggressive chemicals?

9. Can PEEK rods be repaired if damaged (e.g., crack from impact)?

Minor surface cracks can be “healed” via thermal annealing (180–200°C for 1–2 hours), restoring ~80% strength. For deep cracks, replace the component—PEEK’s cost – effective machining makes replacement feasible for lab budgets.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!