Wafer Carrier Trays

Professional design ensures safe transportation and storage of wafers

- High-Quality Materials: Heat-resistant and corrosion-resistant for reliability

- Safety Protection: Prevents scratches, collisions, and contamination

- Strict Quality Control: Rigorous testing ensures industry standard compliance

- Supports small batch customization with delivery in as fast as 5-7 days

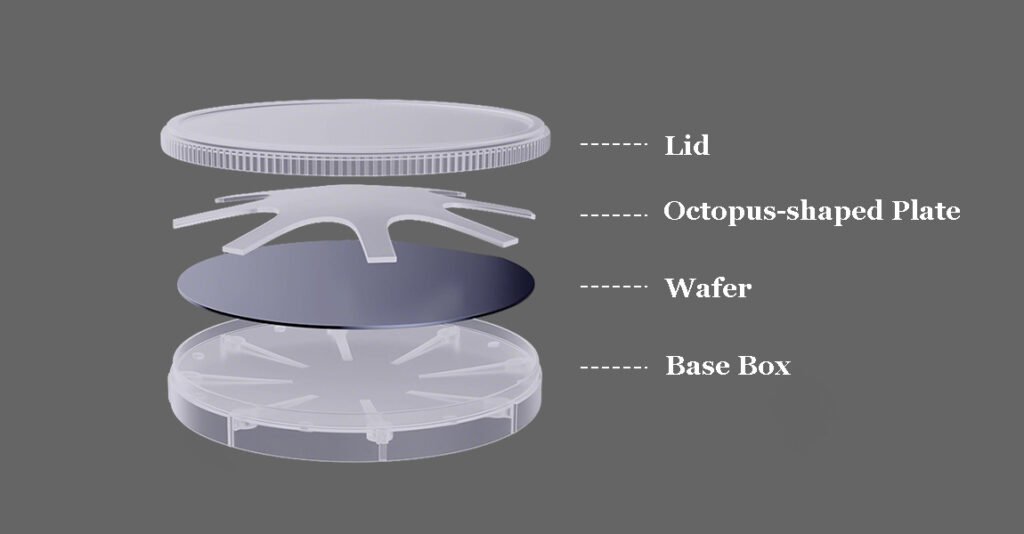

Wafer Carrier Trays Structure:

- Bottom Support Layer: The inner side adopts a curved concave design that only contacts the wafer edge (contact area < 5%), avoiding scratches and contamination caused by direct surface contact. Special anti-slip textures ensure zero displacement when the wafer is horizontally placed.

- Elastic Fixation Layer: Equipped with a spider spring device, it firmly locks the wafer through multi-point elastic support. Tested to withstand ±15g acceleration vibration, it ensures the wafer remains stable during transportation, reducing micro-damage rate by 98%.

- Top Locking Layer: The magnetic sealing cover, paired with an airtight rubber ring, forms a dust-proof barrier to effectively block particle contamination outside ISO 100-class cleanroom environments. The one-handed opening/closing design significantly enhances operational efficiency in laboratories and production lines.

2 series of wafer carrier trays:

1. Transparent Polypropylene Series

2. Anti-Static Black Polypropylene Series

Specifically developed for static-sensitive processes or applications requiring light shielding (such as photoresist-coated wafers), these trays are crafted from anti-static black polypropylene. Infused with carbon materials, the trays achieve a surface resistivity of 10⁴–10⁵ Ω/cm² and volume resistivity of 10⁴ Ω/cm, delivering exceptional ESD (Electrostatic Discharge) protection to prevent wafer damage from charge accumulation. The black material simultaneously forms a natural light-shielding layer, safeguarding photoresist from accidental exposure during transportation and storage.

With stable performance in high-cleanliness environments, these trays are ideal for laboratory wafer transportation, combining edge-support design and spring-locking mechanisms to ensure secure handling.

| Comparison Dimension | Transparent PP Series | Anti-static Black PP Series |

|---|---|---|

| Core Advantages | High light transmittance for real-time visual inspection | Dual functions: ESD protection + light shielding |

| Applicable Scenarios | Laboratory R&D, transportation in conventional cleanrooms | Lithography processes, links sensitive to static electricity/light |

| Material Properties | Light transmittance 92%, high visibility | Surface resistivity 10⁴-10⁵ Ω/cm², anti-static |

wafer carrier tray specifications:

| Prod# | Outer Dimensions(mm) | Compatible Wafer Size | Net Weight(g) |

|---|---|---|---|

| DP1 | 33*9 | 1 inch 25mm | 3 |

| DP2 | 60*12 | 2 inches 50mm | 11 |

| DP3 | 87*13 | 3 inches 75mm | 23 |

| DP4 | 112*15 | 4 inches 100mm | 40 |

| DP6 | 165*20 | 6 inches 125mm | 106 |

| DP8 | 213*20 | 8 inches 200mm | 252 |

| DP12 | 335*50 | 12 inches 300mm | 900 |

The Ultimate FAQ Guide:

1. What are the common materials for Wafer Carrier Trays?

Common materials for Wafer Carrier Trays include quartz, silicon carbide, ceramic, polytetrafluoroethylene (PTFE), and silicon. Different materials are suitable for various process environments. For example, quartz has high temperature resistance and strong chemical stability, making it suitable for high – temperature processes; ceramic features good abrasion resistance and low hygroscopicity.

2. How do I choose a carrier tray suitable for my wafer size?

Wafer sizes mainly include 4 – inch, 6 – inch, 8 – inch, and 12 – inch. When choosing, you need to match the corresponding tray specifications according to the actual wafer size. Also, consider parameters such as the tray’s slot depth and spacing to ensure the wafers are placed stably without friction.

3. What is the service life of Wafer Carrier Trays?

The service life of the tray is affected by factors such as usage frequency, environmental conditions (such as temperature, humidity, corrosive gases), and operating specifications. Under normal circumstances, high – quality trays can be used for 1 – 3 years. If used in harsh environments, more frequent replacements may be required.

4. Can wafer carrier trays withstand high - temperature processes?

Trays made of certain materials (such as quartz and ceramic) can withstand high temperatures, with a maximum tolerance of over 1200°C. However, the specific temperature tolerance should be referred to in the product specification sheet to ensure it meets the process requirements.

5. How to clean and maintain Wafer Carrier Trays?

Generally, use a cleanroom wipe with a special cleaning agent to wipe off surface stains. For stubborn dirt, ultrasonic cleaning can be used. Avoid using sharp tools to scratch the surface. After cleaning, dry the tray in a cleanroom environment to prevent secondary contamination.

6. How is the anti - static performance of the tray ensured?

Anti – static trays are usually made of anti – static materials or coated with an anti – static layer on the surface. During the production process, strict anti – static tests are carried out to ensure that the surface resistance value meets industry standards (such as 10⁶ – 10¹²Ω).

7. Do you provide customized Wafer Carrier Trays services?

We offer customization services. We can design and produce exclusive trays according to customers’ requirements for wafer size, special process requirements (such as high – temperature resistance, anti – static level), and loading quantity.

8. Are there discounts for bulk purchases of Wafer Carrier Trays?

Bulk purchases can enjoy tiered discounts. The specific discount rate depends on the order quantity and product type. For details, please contact our sales team for a quote.

9. What is the delivery time for the products?

Standard products are usually shipped within 7 – 15 working days. The delivery time for customized products will be evaluated according to the complexity, generally 20 – 45 working days.

10. Is the packaging of Wafer Carrier Trays suitable for long - distance transportation?

We use anti – static and cleanroom packaging and fill it with cushioning materials to ensure that the trays are not damaged by vibration and extrusion during transportation. At the same time, the packaging meets international transportation standards and can be safely delivered worldwide.

11. Are the products certified by international quality standards?

Our Wafer Carrier Trays have passed the ISO 9001 quality management system certification. Some products also comply with SEMI international semiconductor equipment and materials standards, ensuring reliable quality.

12. How to handle it if the tray is damaged during use?

If there is non – man – made damage within the warranty period, we provide a free replacement service. Outside the warranty period, we also offer repair or preferential replacement solutions. For details, please contact our after – sales customer service.

13. What is the load - bearing capacity of the tray?

The load – bearing capacity varies for different tray specifications. Generally, a single – piece wafer carrier tray can bear a weight of 5 – 15 kg. For detailed parameters, please refer to the product technical document.

14. Can samples be provided for testing?

We can provide samples for customers to test. The sample cost and freight will be negotiated according to the specific situation. Bulk purchases can be made after satisfactory testing.

15. What should be noted when using Wafer Carrier Trays in a cleanroom?

Before use, unpack the tray in a cleanroom environment and perform secondary cleaning. Operators need to wear cleanroom clothing, gloves, and other protective equipment to avoid contaminating the tray and wafers.

16. Are the trays compatible with wafer processing equipment from different brands?

Our standard trays are designed in line with industry – wide common interface specifications and can be compatible with most mainstream brands of wafer processing equipment. If there are special equipment requirements, please inform us in advance for compatibility confirmation.

17. How to store unused Wafer Carrier Trays?

They should be stored in a clean, dry, and thermostatically controlled environment, away from direct sunlight and contact with corrosive substances. Special storage racks or packaging boxes can be used for storage.

18. What is the price range of the products?

The price varies depending on factors such as material, size, and customization requirements. The price range for standard products is XX – XXX US dollars per piece. For customized products, a quote will be provided according to specific requirements.

19. Do you provide technical support and training services?

We provide comprehensive technical support, including installation guidance, usage training, and after – sales consultation. If necessary, engineers can be arranged to provide on – site technical services.

20. What is the positioning accuracy of Wafer Carrier Trays for wafers?

Our trays adopt high – precision processing technology, and the positioning accuracy of the slots can reach ±0.01mm, ensuring the stability and consistency of wafers during transmission and processing.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!